Case study: Cyprus Bakery Chain Zorbas Choses R290 Waterloop Systems

Cyprus Bakery Chain Zorbas Chooses Waterloop Systems With Natural Refrigerant R290 for Refrigeration

With the new cooling system in two bakery stores, Zorbas confirms its statement as a nature-friendly chain, saving up to 30% of energy demand.

About the store

Zorbas Bakery has a long history on the island of Cyprus, located in Europe’s South. Starting as a family-run bakery in 1975, the company has stayed true to its values: quality, consistency, and constant development. Zorbas has grown successfully, opened 66 bakeries in the island’s main cities such as Nicosia, Limassol, Larnaca, Pafos and Famagusta, and even expanded into the U.S. market in 2015.

The company’s current product portfolio includes baked goods as well as desserts, salads, snacks and hot beverages. The company describes itself as “nature- friendly.”

Climate friendly cooling

To meet the refrigeration needs of its two new bakeries opened in January 2022 and located in Paphos and Limassol, Cyprus, Zorbas Bakery has chosen a propane (R290) waterloop design called Hydroloop WPI (water pump integrated) system. In this system each cabinet in the store has a small integrated water/glycol pump.

Lithuanian equipment manufacturer Freor provided 4 multideck cabinets of different sizes (JUPITER) and 13 freezers of two different sizes (ERIDA, ERIDA SLIM) for each of the new stores. All the installations run with the Hydroloop Glycol WPI system.

According to Freor, the design of the system allows for up to 30% energy savings in comparison with a normal designed glycol circulation setup. Efficient operation of the pumps is key for good performance, as they run individually up to 16 hours per day in synchronisation with the compressor. This reduces the energy consumption compared to a traditional hydroloop system which would require energy for 24 hours per day. The system also eliminates the needs for a central pump station, saving space in the store. As each cabinet operates independently, cold storage can be guaranteed even in case of a malfunction of one appliance.

Convincing features

Simplicity, flexibility and ease of installations convinced Zorbas to choose the Hydroloop Glycol WPI system. The cabinets can be moved according to the needs of the store, as they “only need to be connected to hydraulic piping and plugged into electrical outlets, something that a plumber can do,” specified Dominyka Germanaitė, Marketing Manager at Freor. In pursuit of further energy savings, Zorbas also opted for cabinets with glass doors in its two new stores.

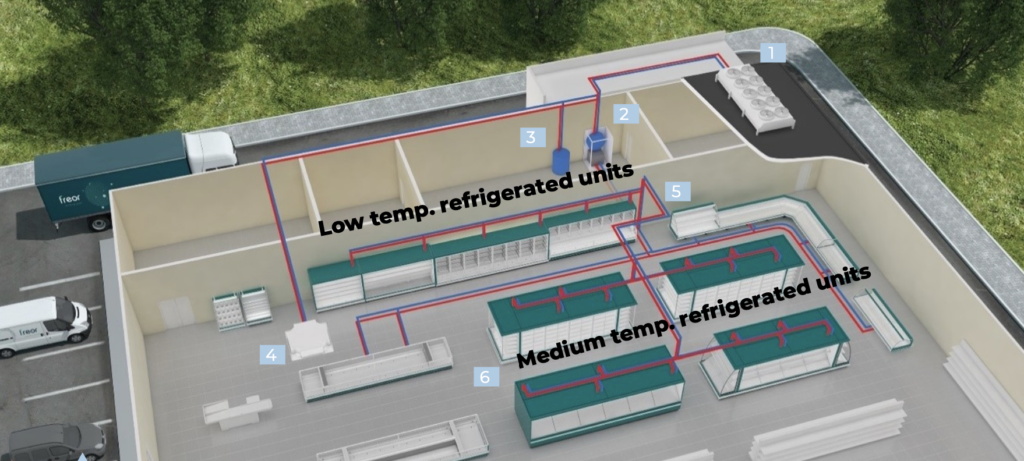

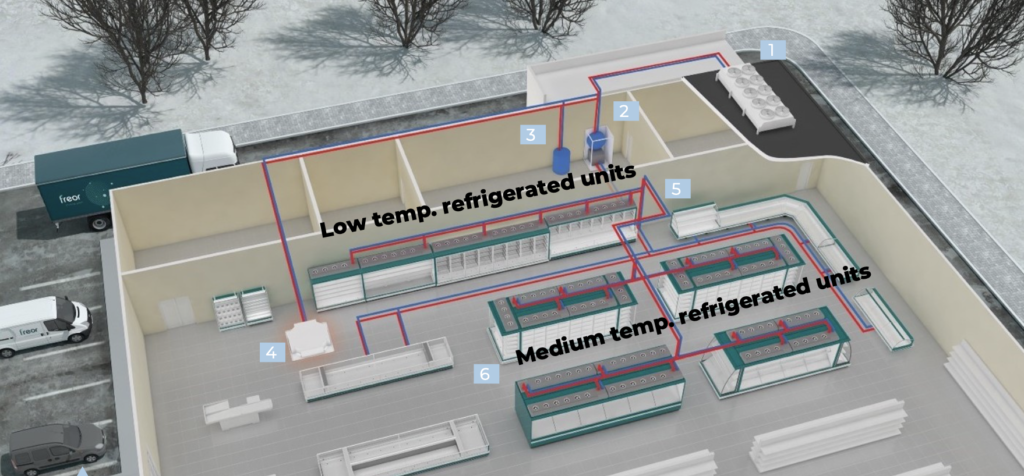

About the system:

- Dry cooler for thermal output in summer period.

- Pump station to ensure glycol circulation in closed loop.

- Hot water tank (optional).

- Sales area heating (optional).

- Heat removal via glycol line.

- Direct heat output into the sales area in winter period

How does a hydroloop refrigeration system work?

- allows connecting the plug-in refrigeration equipment to a glycol- cooled system, in which excess condensation heat is removed through closed-cycle liquid pipes to the exterior of a building in summer

- use of the heat for warming up the store and water in winter via direct emission into the store through air condensers mounted on the units

- one loop only for both medium and low temperature display cases

- easy integration with heat reclaim system